Let's get in touch.

Ernesto Flores, Headquarters Plattling

ContactMaintenance

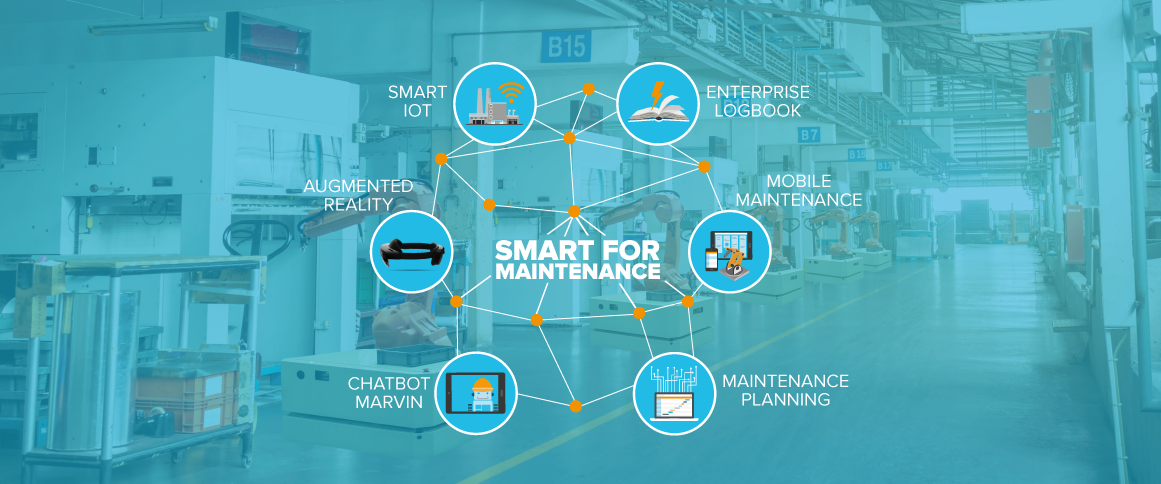

As the digital transformation advances and Industry 4.0 takes off, there is a sharper focus on the role of maintenance to economic success. New, innovative technologies can be used to make maintenance measures more efficient and improve the availability of production plants. However, lots of companies just stick to the rudimentary functions of SAP PM/EAM and never exploit the full potential it offers for process support. Our products and add-ons provide targeted extensions to the core functionality and make maintenance processes noticeably more efficient.As the digital transformation advances and Industry 4.0 takes off, there is a sharper focus on the role of maintenance to economic success. New, innovative technologies can be used to make maintenance measures more efficient and improve the availability of production plants. However, lots of companies just stick to the rudimentary functions of SAP PM/EAM and never exploit the full potential it offers for process support. Our products and add-ons provide targeted extensions to the core functionality and make maintenance processes noticeably more efficient.

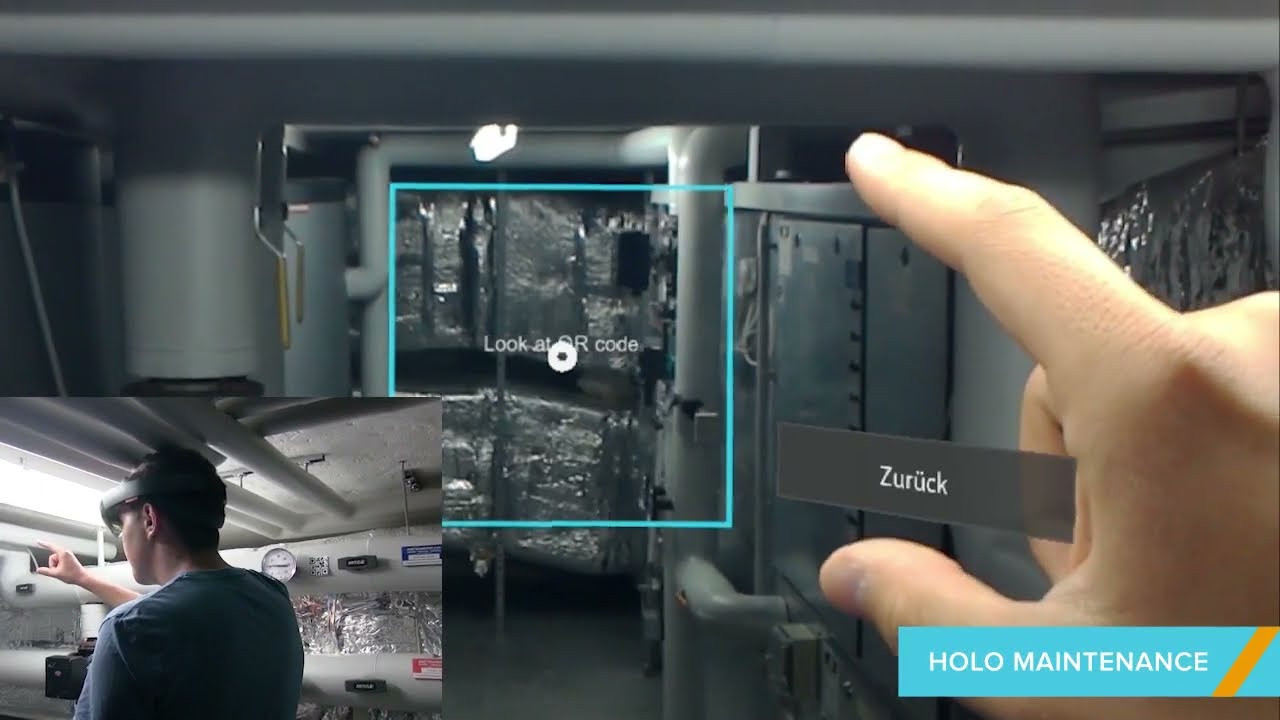

Through numerous projects, we have developed a clear understanding of the typical challenges and gaps in SAP PM – from mobile user experience to planning; from reporting through to machine connections and IoT. We have put together suitable solution approaches and best practices in our “SMART FOR MAINTENANCE” package, along with innovative supporting functions such as chatbots and augmented reality.

Use SMART FOR MAINTENANCE to...

Use SMART FOR MAINTENANCE to...