Let's get in touch.

Ernesto Flores, Headquarters Plattling

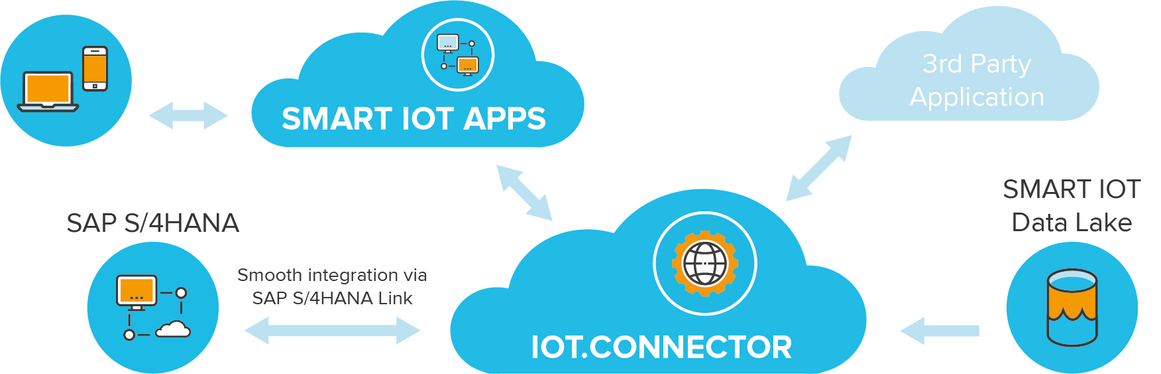

ContactThe majority of these IoT datasets are never used – they’re just too big and complex. SMART IOT gives enterprises tools to make use of this data to benefit from IoT in Manufacturing. We link automatically generated business and production data to your IoT data. This is done with our IOT.CONNECTOR, bridging the gaps between your ERP and MES systems, right down to the data capture infrastructure.

Your data can now be linked to your corporate objectives. It can be used directly in machine learning applications to support and optimize your workflows. The spectrum of use case scenarios ranges from optimized machine configuration through to developing analysis tools. The data can also be used to predict process stability and quality and even for energy management.

Our SMART IOT apps are individually developed IoT microservices designed to enable you to implement custom IoT use cases with minimal effort. We support our customers with our best practices and guide you through the implementation. This is a particularly ideal solution for small and medium-sized customers without IT infrastructure: it allows you to benefit from rapid project launch and individual use cases.

With SMART IOT

With SMART IOT

Optimized production with a Golden Batch

A machine operator uses our “Golden Batch” application to define the optimal machine settings for various tasks. Relevant process data such as quality, tonnage or duration is linked with IoT data from the ERP. Although conditions vary on a case by case basis, this foundation ensures the machine always produces an optimized output. The stakeholders select “Golden Batches” manually. Based on these historical “Golden Batches”, the algorithm learns the best settings for the current production order.

Predictive Maintenance

If you continuously collect and evaluate shop-floor data, you can implement condition monitoring without having to install new, expensive sensor systems. ML algorithms analyze bulk data – past and present – to predict that, say, there is a 90% chance that a particular machine will fail in the next 50 hours. The machine operators can take proactive steps to prevent the failure before it’s too late.

Identifying production defects

A company receives a complaint from one of their customers about the poor quality of a delivered product. Various user groups in Production want to know what went wrong: managers, machine operators, production managers, etc. To achieve this, sensor and machine data are automatically linked to production data.